Boiler Room Conversions and Modernization

Optimizing Plant Operations

Efficiency & Safety play a crucial role in industrial and commercial boiler operations, impacting energy expenses, environmental factors, and overall productivity.

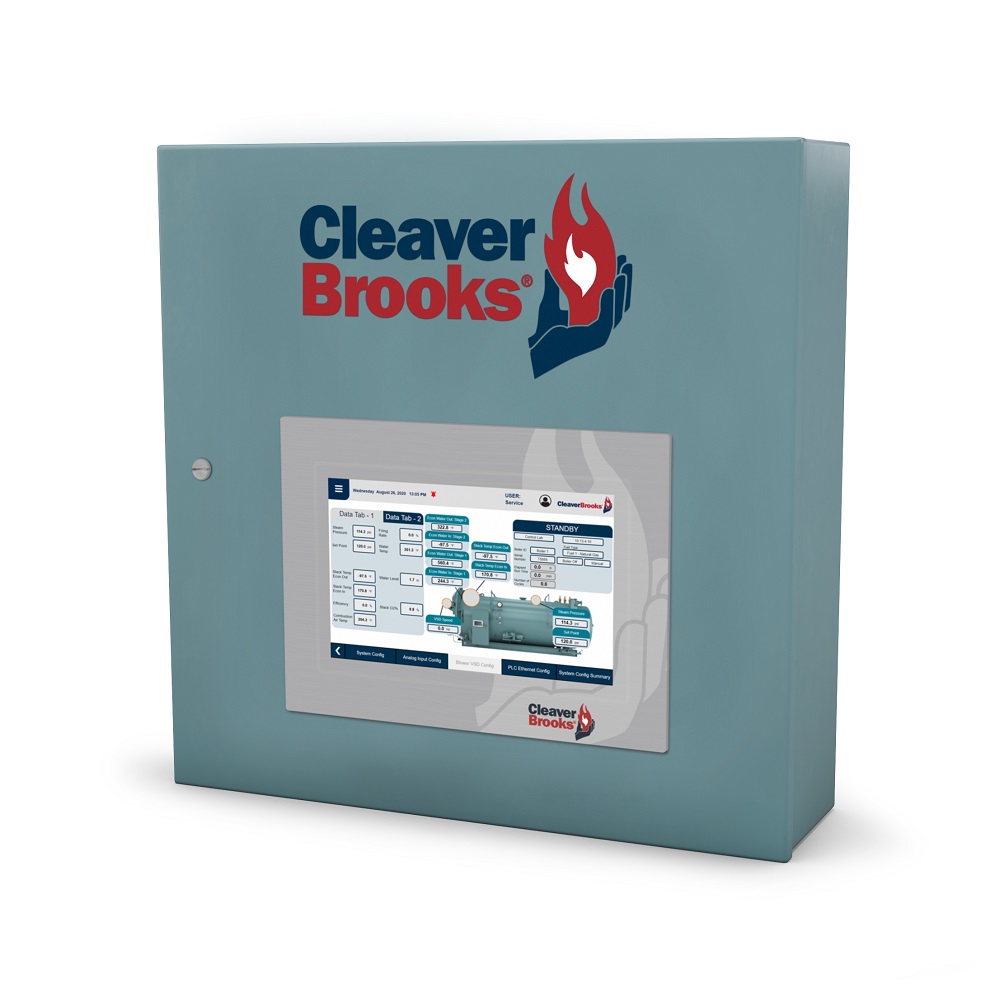

Communicate with your boiler room using Prometha®

Communication is key to better understanding an on-going issue with your boiler plant. Consider leveraging Prometha connected boiler solutions to maximize or improve your boiler room.

With Prometha, you can remotely monitor your boiler system, receive real-time insights, diagnose issues, and analyze performance trends. More than viewing data, Prometha transforms this data into actionable results that steer your boiler operations towards improved efficiency and reliability.

Ready to upgrade or update your boiler plant?

Contact a Cleaver-Brooks rep today to schedule a consultation with one of our experts. Whether you're interested in conversions, retrofits, modernizations, or simply seeking advice, we're here to help.