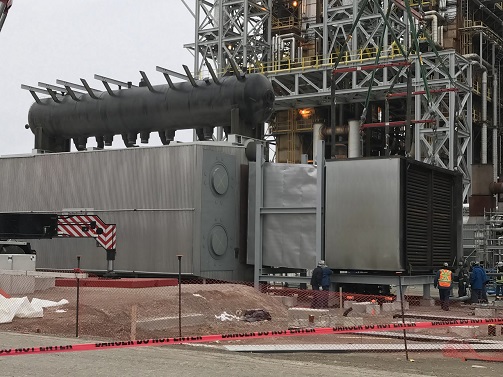

Five natural gas-fired, shop-assembled integrated boilers capable of generating 426,000 lb/h of saturated steam at 550 psig were manufactured in Lincoln, Nebraska, and commissioned in Canada. These packaged boilers were different from the typical D-type boilers in two major respects. First, the design used an elevated drum with external downcomers and risers, which helped to increase the furnace and convection bank dimensions while maintaining the ability to ship the units. In addition, a glycol-based, closed-loop heat-recovery system consisting of three finned tube heat exchangers was incorporated to improve boiler efficiency by about 2.3% and to increase the air temperature to the forced draft fan in severe winter conditions, when -30°F to -40°F is likely to be the ambient temperature.

The first unique design feature on this packaged boiler was the elevated steam drum. The boiler shipping envelope is not constrained by the drum size, as headers are used for the evaporator module. Furnace heat flux evaluation was performed based on inputs from the burner supplier, as the flame temperature varies along the flame path, affecting the local heat flux and steam generation. Heat flux and circulation calculations were performed to ensure proper sizing and location of downcomer and riser piping.

The second novel feature was the use of a closed-loop glycol recirculation system to improve boiler efficiency. The typical economizer exit gas temperature in natural gas-fired packaged boilers is about 300°F with 230°F feedwater temperature. On this project, the exhaust gas temperature was reduced to 215°F (uniquely lower than the 230°F feedwater temperature) using a closed-loop glycol heating system that transfers heat from the exhaust gas to the incoming combustion air.