Steam Boilers: A Comprehensive Guide

Steam Boilers for Industrial and Commercial Use

Explore our advanced steam boiler solutions designed to optimize industrial and commercial operations with unmatched efficiency and reliability. This guide provides comprehensive insights into steam boilers, their components, applications, and strategies for improving system performance, sustainability and safety.

How Do Steam Boilers Work?

Steam boilers generate steam by heating a combination of chemically treated softened water or RO water and returning condensate. The steam is then used in various industrial and commercial applications. Here’s a detailed look at the process and the types of systems used:

Basic Process

- Heat Source: A fuel source (natural gas, oil, coal, or electricity) creates a flame or hot gases to heat the boiler water or via the electric elements in an electric steam boiler.

- Heating the Water: The heat transfers to the water, either directly (firetube boilers), through surrounding tubes (watertube boilers), or direct contact with water (electric boilers)

- Steam Generation: The heated water reaches the boiling point, converting to steam.

- Steam Distribution: The steam is distributed through pipes to its application points.

Types of Steam Boilers and their Solutions

Firetube Boilers: These boilers have a flame that passes through enclosed tubes, heating the surrounding water. Firetube boilers are generally used in commercial and small industrial applications.

Watertube Boilers: These boilers heat gases in a furnace that circulates around water-containing tubes. Unlike firetube boilers, watertube boilers can handle higher pressures, making them ideal for demanding industrial processes.

Electric and Electrode Boilers: These boilers use electricity to heat water or generate steam, offering an efficient and emission-free alternative to traditional fuel-fired systems. Electric boilers rely on heating elements, while electrode boilers pass an electric current directly through the water to produce heat. Both types are ideal for applications where space, emissions, and efficiency are important considerations. Electric boilers are well-suited for residential, commercial, and industrial uses, while electrode boilers excel in a broad range of industrial settings that demand rapid steam generation and very large turn down capabilities.

Our Steam Boilers

Essential Components of Steam Boiler Systems

Our steam boiler systems feature key components to ensure optimal performance reliability and safety:

- Pressure Vessel: Built to meet or exceed ASME standards to withstand extreme temperatures and pressures for safe operation.

- Burner System: Utilizes precision combustion technology for maximum fuel efficiency and low- to-ultra-low emissions.

- Control Systems: Advanced monitoring ensures precise operation parameters and enhanced efficiency.

- Heat Transfer Mechanisms: Use sophisticated technologies to maximize thermal efficiency.

- Water Treatment Solutions: Prevent scale buildup and corrosion, ensuring water purity, and extending boiler lifespan.

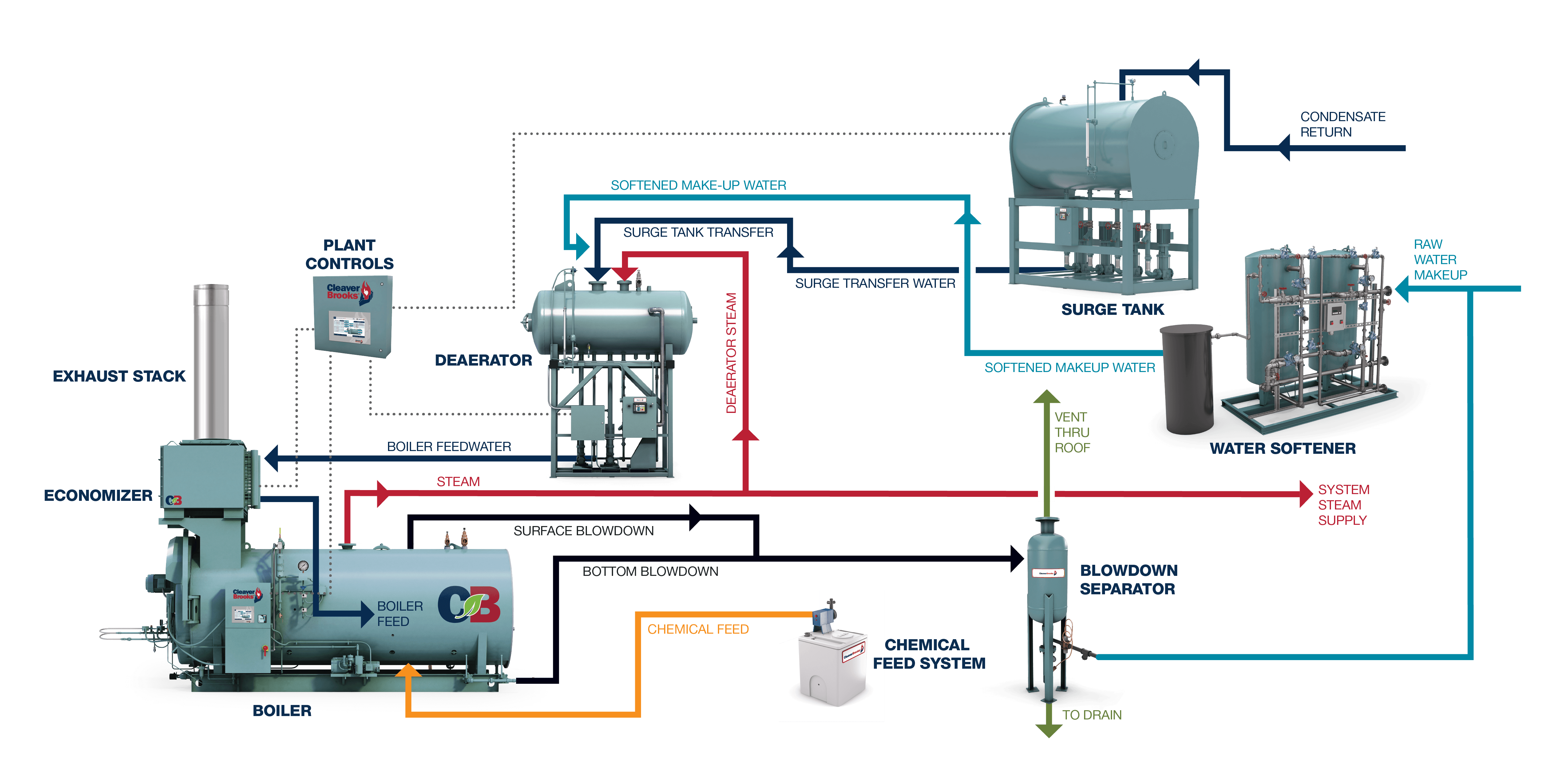

Steam Boiler Room Equipment and Accessories

Enhance your steam boiler system with high-quality equipment and accessories designed to optimize performance and efficiency:

- Economizers: Capture waste heat from flue gases to preheat feedwater.

- Deaerators: Remove dissolved gases from feedwater to prevent corrosion.

- Blowdown Separators: Safely handle blowdown water by cooling it for safe disposal.

- Feedwater Systems: Ensure a consistent supply of treated water.

- Heat Recovery Systems: Capture and reuse heat to improve overall energy efficiency.

- Chemical Feed Systems: Control chemical dosing to maintain optimal water chemistry.

Our Boiler Room Equipment & Accessories

Enhancing Boiler Efficiency

Achieve peak efficiency with our advanced boiler technologies:

-

Near perfect Combustion : Optimize energy conversion to minimize fuel consumption resulting in high fuel to steam efficiency.

-

High Turndown Ratios: Allow flexible operation to adjust steam output based on the demand.

Steam Boiler Safety and Reliability

Safety and reliability are is paramount in our steam boiler designs:

-

Innovative Safety Features: Advanced safety features such as pressure relief valves and low-water cutoffs prevent hazards.

-

Planned Maintenance: Routine maintenance minimizes downtime and increases asset lifespan.

Applications of Steam Boilers Across Industries

Steam boilers are essential across many industries, providing critical steam for various applications:

-

Manufacturing: Used for heating, cleaning, and powering machinery.

-

Chemical Production: Used for heating, distillation, reaction heating, and finished product drying.

-

Food Processing: Ensure food safety through sterilization and pasteurization.

-

Pharmaceuticals: Create sterile environments for equipment and product manufacturing.

-

Oil and Gas: Generate Hot water and steam to produce electricity.

-

Commercial Applications: Provide heating for buildings, hot water for hospitality services, and sterilization for healthcare facilities.

We Need Steam! Hurry, Fire Up The Boiler Below!

Click the button below to start up the CBEX-3W firetube boiler to generate steam!

.gif)

Your boiler’s working—but could it perform better?

Your system may be running, but is it performing at its peak performance? Ensure efficiency, safety, and reliability with our solutions. Find parts, connect with an authorized C-B representative, or optimize your boiler system.

Frequently Asked Questions (FAQs) About Steam Boilers

What types of steam boilers are available?

There are three main types of steam boilers: firetube, watertube, and electric. Firetube boilers are compact and efficient, with combustion gases passing through tubes to heat the water, making them ideal for commercial and small industrial applications. Watertube boilers circulate water through tubes surrounded by combustion gases, making them suitable for high-pressure applications and large steam capacities. Electric boilers use heating elements to generate steam, offering an energy-efficient and emission-free alternative for residential, commercial, and smaller industrial uses.

How can boiler efficiency be improved?

To improve boiler efficiency, optimize combustion by maintaining the proper air-to-fuel ratio and adding advanced control systems for real-time monitoring and adjustments. If the boiler pressure vessel is in good shape, replacing an older burner will immediately improve efficiency. Regular maintenance, such as descaling and checking for leaks, also helps keep a boiler operating efficiently. Adding a condensing or standard - Flue gas economizer can also boost your efficiency.

Which industries benefit most from steam boilers?

Many industries use steam boilers, including manufacturing, food processing, pharmaceuticals, healthcare, hospitality, education, government, chemical processing, paper mills, petroleum and utilities.

In manufacturing, boilers provide heating, cleaning, and power for machinery. In food processing, they ensure safety through sterilization and pasteurization. Pharmaceuticals use them for creating sterile environments, while healthcare facilities rely on them for heating and sterilization. In buildings, on college campuses, and in the hospitality industry, boilers supply heating and hot water.

High-pressure steam is used in many industries including chemical processing, paper mills, petroleum and utilities. In the chemical industry, boilers are used for heating, distillation and reaction heating, and in pulp and paper mills, they are used to power machinery. In the oil and gas industry, high-pressure steam boilers generate hot water and steam for drilling operations, and in the utility industry, they are used for power generation.

What measures ensure boiler safety?

Boilers have advanced safety features such as pressure relief valves, flame monitoring, and low- water cutoffs for safety. Adhering to boiler safety standards and regulations and performing regular maintenance further ensure boiler safety. Proper training for operators is also crucial so they know how to operate the boiler safely and respond to emergencies. Proper boiler combustion controls and boiler safety monitoring controls also contribute to long life and safe operation.

Discover Advanced Steam Boiler Solutions

Explore our comprehensive range of steam boiler solutions tailored to optimize industrial or commercial processes with reliability, efficiency, safety, and sustainability. For more information, contact your local Cleaver-Brooks representative or call 1-800-250-5883 to find the perfect steam boiler solution for your needs.