Within the condensing boiler segment, there are a variety of technologies available. Some condensing boilers require more maintenance than others, or have specific piping, pumping, and flow requirements. High mass firetube condensing boilers have been developed to overcome many of these obstacles, and can be piped in a variety of systems with success. Therefore, it is important to understand each boilers’ operating requirements, as well as total cost of ownership, when making a boiler selection.

Below are just three of the seven myths that are discussed in this paper:

Myth -- We Need to Maintain a 20°F System ΔT. Older systems typically maintain a low ΔT in order to keep the hot water return temperature above condensing conditions. In condensing systems, temperature differentials of 30°F or higher can be designed to increase boiler efficiency by lowering the hot water return temperature back to the boiler.

Myth -- Hot Water Reset Doesn't Work. Hot water reset is a simple control strategy that has been used for many years on hot water systems with a lot of success. With condensing boilers, the hot water reset functionality based on outside air is generally built in, making this a relatively low- or no-cost item to implement within the system.

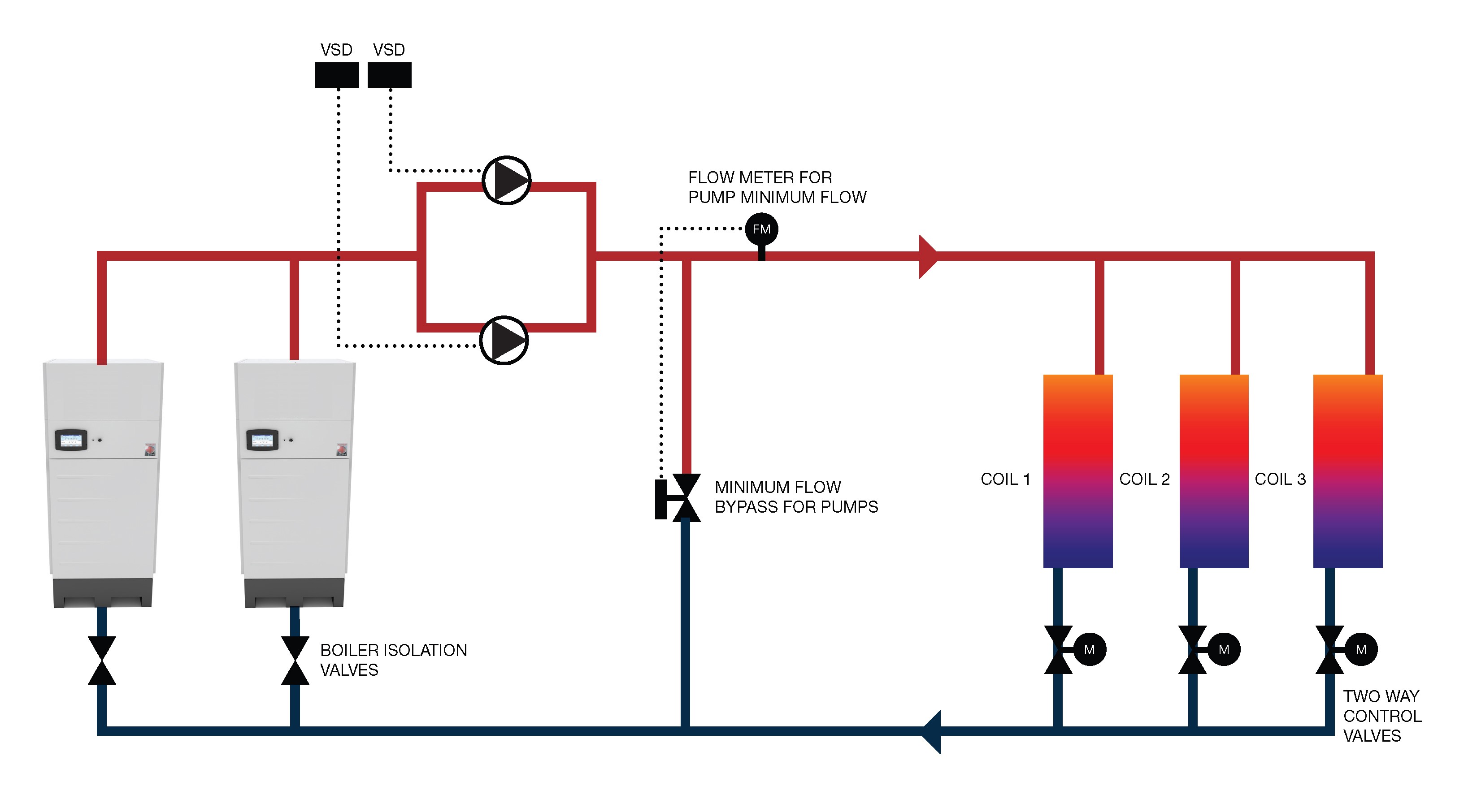

Myth -- Variable Flow Primary Systems are More Complex. In actuality, variable flow primary systems are simpler than primary secondary systems as variable flow primary systems only require one set of pumps to handle everything in the system. Also, there is no mixing due to two hydraulically separate pumping loops and less equipment is required, so there are fewer devices to control. In variable flow primary systems, there are three items that must be addressed for proper system operation.