{{ 'Sustainable Boiler Plant Solutions' | limitTo: 50 }}

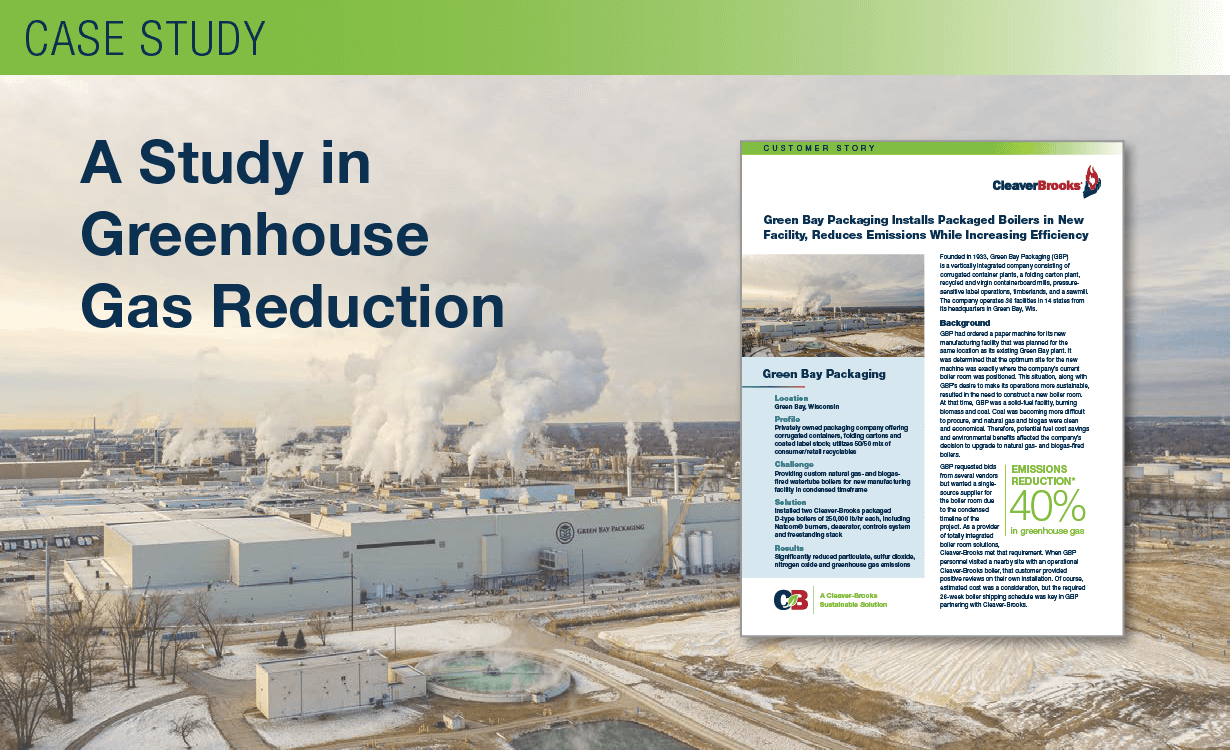

Due to a heightened awareness of environmental issues and their impact on future generations, sustainability is a key focus for most companies around the world today. The Cleaver-Brooks Sustainability brochure details environmentally responsible steps companies can take toward a low-carbon economy. The brochure identifies key drivers, a range of solutions, and equipment recommendations to guide companies in achieving their sustainability goals.

.png)

.jpg)

.png)

.png)

.png)