Utilizing Renewable Fuels in Burner Systems

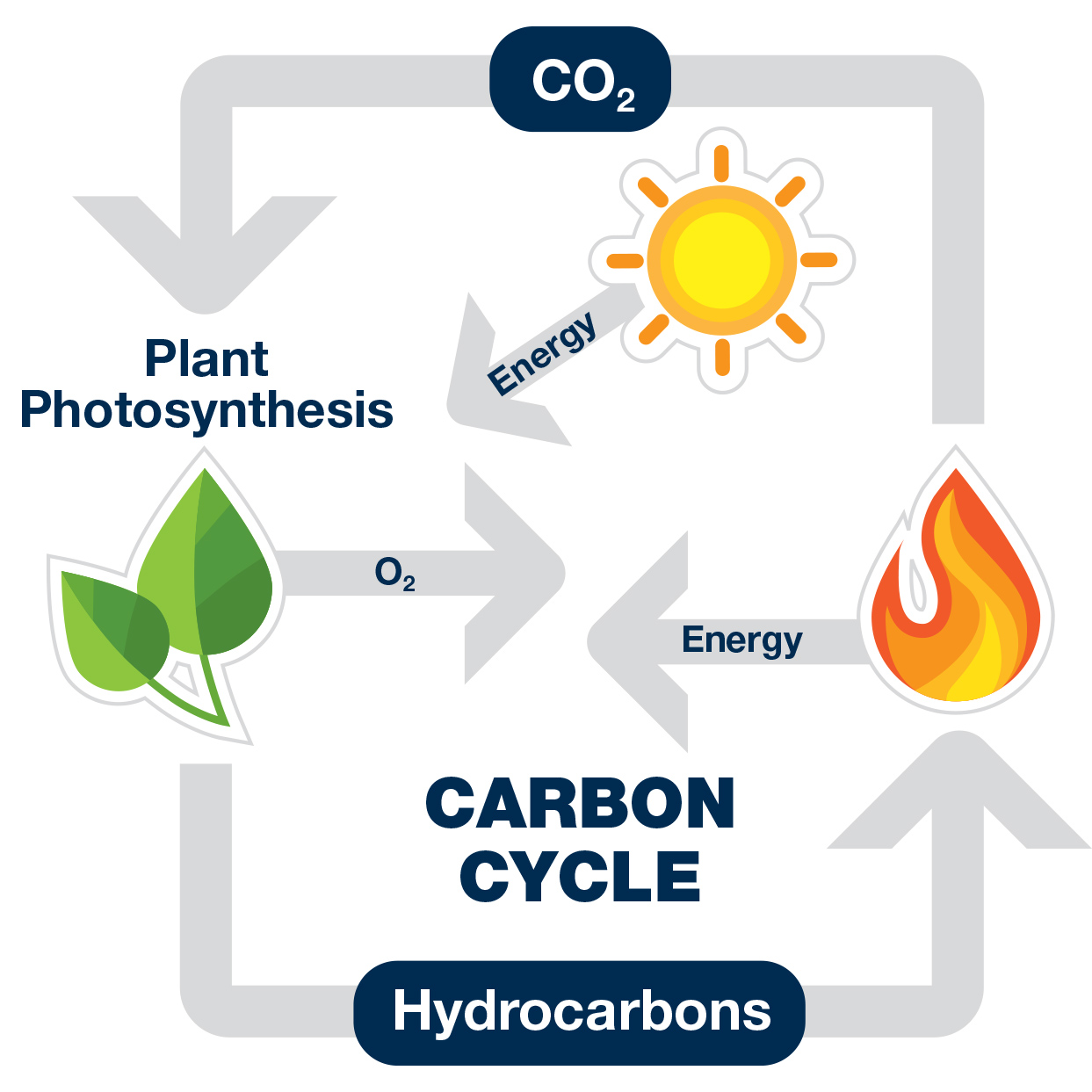

Thomasville, Ga. (April 30, 2021) – Renewable fuels are fuels produced from renewable resources. Examples include biofuels made from biomass and hydrogen produced with electricity made from tidal, wind or solar energy. Renewable fuels produced from biomass generally start as plant material. As depicted by the carbon cycle principle (see graphic below), growing plants absorb CO2 from the air and convert it into hydrocarbon through the process of photosynthesis. Energy, which is provided by the sun, is required to break up the CO2 molecule and rearrange it with other elements to produce the new plant material. The photosynthesis process also produces oxygen that is returned to the atmosphere. When biomass is used to produce energy, the hydrocarbons are transformed back into CO2, which releases energy that can be used in different ways. For example, an area of land produces wood that is used as fuel to heat a building. The CO2 from wood combustion is then used to grow the trees in this same area, thus closing the loop.

The food processing industry can benefit from utilizing renewable fuels. Cleaver-Brooks has installed biogas/conventional fuel burners in potato processing, breweries, rendering and other food processing plants. The feedstock used is renewable (vegetables, cereals, fruits) and, in many cases, a portion of the biomass input will be discarded as waste. Instead of paying to dispose of this waste, it can be used to produce fuel. This greatly reduces the mass of final waste and offsets the consumption of fossil fuel normally used in the process.

The transformation of the biomass waste into fuel is done in a reactor that uses a digestion process to produce the biogas, which is a mixture of methane, CO2 and water. The biogas can be fed to a boiler with a purposely-built burner that typically fires the biogas and a conventional fuel such as natural gas or fuel oil. This arrangement is very flexible as the burner will fire the available biogas and supplement the heat input with conventional fuel so that the steam demand can be met at all times. Also, the conventional fuel is used when the processing facility is starting up and no biogas is available.

In certain cases, biogas cannot be produced at the source but occurs downstream at municipal wastewater treatment plants and landfills. Wastewater plants produce a sludge that must be discarded. Again, a digester reactor will produce methane-rich gas with this sludge. The digester gas can then be fired to produce energy. In landfills, the production of methane happens underground as the biomass is decomposing. Because methane gas has 25 times the greenhouse gas effect of CO2, it is environmentally preferable to collect the methane and combust it to CO2 before releasing it into the atmosphere. Thus, producing useful energy with landfill gas becomes a win-win situation.

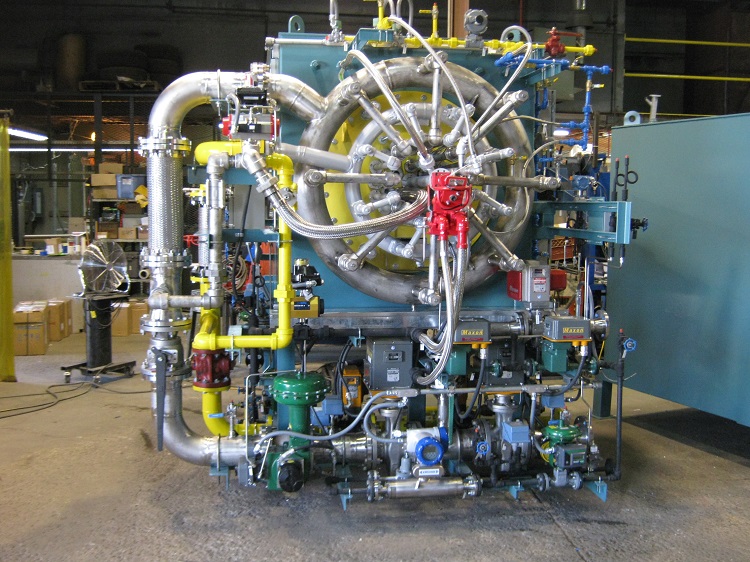

Renewable fuels already include a wide range of liquid and gaseous options. New production processes will bring even more possibilities in the future. Cleaver-Brooks offers both custom and standard burner solutions for these fuels. The custom burners are specifically designed to fire the liquid and/or gaseous fuels of your choice. These low-NOx burners can fire more than one fuel at a time and utilize controls that can adapt the individual firing rates based on fuel availability while meeting the steam demand of the plant. We are closely monitoring the progress made in renewable fuel technologies and evaluating our standard burner product line for use with these innovative fuels. Cleaver-Brooks remains on the forefront of renewable fuel burner development.

Burner Image Cutline: Cleaver-Brooks burner designed to fire natural gas, #2 oil and a renewable fuel

By Normand Bujold

Vice President of Application and Technology

Industrial Burner Division

About Cleaver-Brooks

Cleaver-Brooks, a world-renowned provider of boiler room products and systems, is committed to providing efficient solutions that help its customers and the industry reduce energy usage, cost and environmental impact. As the pioneer of packaged firetube and watertube boilers, Cleaver-Brooks is the only manufacturer in the world to offer an entirely integrated boiler room solution for any size application. Its products are backed by a world-class representative network offering superior aftermarket service and solutions. Visit cleaverbrooks.com for more information.

# # #