MiniMate® Deaerator

- Packed column deaerator

- 2,000 - 7,000 lbs/hr

- On/off pumping

The MiniMate® deaerator is a pressurized packed column design where water passes through a labyrinth of packing materials specially designed to agitate water and remove dissolved oxygen and carbon dioxide in boiler feed water.

- Product Overview

- Related Resources

- Applications

The MiniMate Packaged Deaerator – Built for Small-Scale Steam Applications

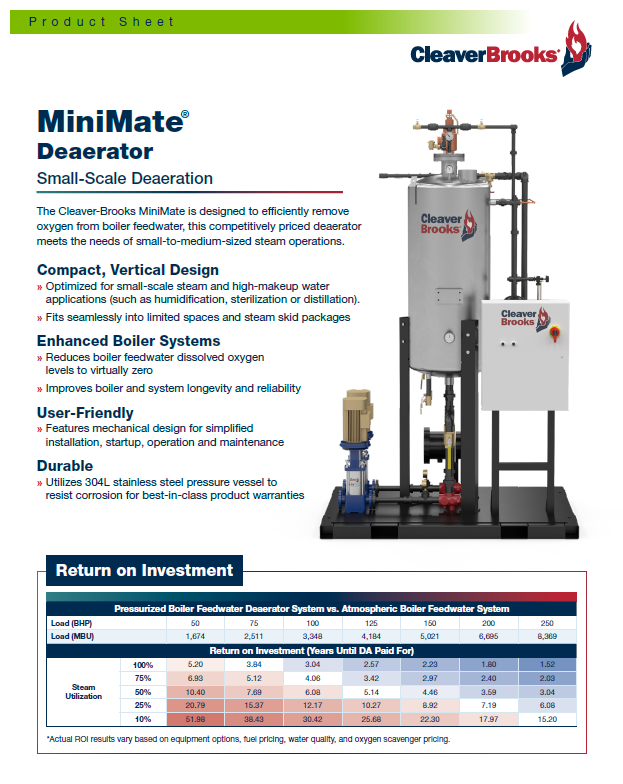

The Cleaver-Brooks packaged deaerator is a miniaturized version of the renowned BoilerMate design, specifically optimized for small-scale steam applications. Its compact, vertical tank arrangement fits seamlessly into tight spaces and steam skid packages, making it ideal for facilities with space constraints.

Featuring a mechanical design that simplifies installation, startup, operation, and maintenance, this deaerator offers convenience and efficiency. The standard stainless-steel construction of both the tank and pumps ensures reliability, durability, and long service life.

- Packaged, pressurized boiler feedwater system

- Produces deaerated water, protects boiler systems and piping from oxygen pitting

- User friendly, no PLC

- Durable, corrosion resistant design

MiniMate Product Sheet →

WEBINARS

Understanding and Optimizing Boiler Feed Systems →

C-B Finally Spills It! What You Should Know About Boiler Feedwater Systems →

Improving the Reliability and Efficiency of Your Steam Boiler →

How to Protect Boiler System Efficiency and Integrity with Water Treatment →

- Process Steam

- Building Heat

- Sterilization

- Humidification

- Laundry and Dry Cleaning

- Food Processing

- Breweries & Distilleries

- Pharmaceutical

- Renewable Energy