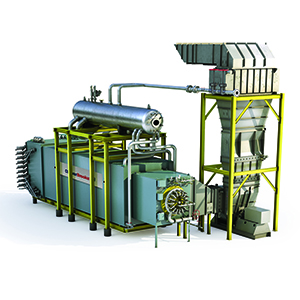

Forced Circulation OSSG Boiler

- Assembly: Shop or Field Assembled

- Steam Flows (lb/hr): 200,000 - 500,000

- Construction: Membrane Wall Construction

- Emissions (ppm NOx): <5

- Steam Temperature: Saturated

- Fuel: Natural Gas, #2-#6 Oil, Refinery Fuels, Alternative Fuels

- Circulation: Forced Circulation

- Type: FC-OSSG

- Saturated steam

- 200,000 to 500,000 lb/hr

- Natural Gas, #2 - #6 oil, refinery fuels, alternative fuels

- Design pressure up to 2,300 psig

- Available to less than 5 ppm NOx, Ultra-Low CO

The Cleaver-Brooks Forced-Circulation Oil Sands Steam Generator (FC-OSSG) combines the benefits of a traditional D-style watertube boiler, with high steam purity and very low blowdown, and the ease of cleaning of once-through steam generators (OTSG).

- Product Overview

- Related Resources

- Applications

- Highly efficient steam solutions capable of meeting strict emissions requirements

- Increased efficiency with minimal blowdown.

- 10:1 turndown.

- Single-source integrated boiler/burner/control package engineered to work together.

- Smaller footprint for reduced material cost and space savings.

- Shipped modular for ease of installation.

- 100% mechanically cleanable by pigging.

This large-capacity steam generator is uniquely suited for the needs of the oil sands market and is ideal for use in SAGD applications utilizing produced water.

CASE STUDY

BYU Replaces Coal-Fired Boilers →

BYU replaced coal boilers with two O-type watertube boilers, a CBEX Elite firetube boiler and a HRSG, and pursued independence from local electrical grid.

Buffalo Trace Installs New Boiler System →

Buffalo Trace was able to meet changing steam demands, significant fuel savings and reduced emissions.

WHITE PAPER

Forced-Circulation Steam Generators for SAGD Applications →

Cleaver-Brooks Forced-Circulation Oil Sands Steam Generator Video →

- Oil Sands & Petroleum