Modular Industrial Watertube Boiler

- Assembly: Shop Assembled

- Steam Flows (lb/hr): 200,000 - 1,000,000

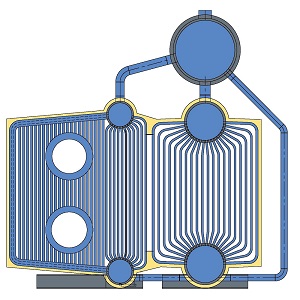

- Construction: Membrane Wall Construction

- Emissions (ppm NOx): <5 with SCR

- Steam Temperature: Up to 1,050 deg F

- Fuel: Natural Gas, #2-#6 Oil, Refinery Fuels, Alternative Fuels

- Circulation: Natural Circulation

- Type: Modular

- Steam, temperatures to 1,050°F

- 200,000 to 1,000,000 lb/hr

- Natural Gas, #2 and #6 oil, refinery fuels, alternative fuels, combination

- Design pressure up to 2,300 psig

- Available to less than 5 ppm NOx, Ultra-Low CO

The Cleaver-Brooks Modular (MED) Industrial Watertube boiler provides up to 1,050°F superheated steam in a modular unit.

IWT boilers can fire renewable natural gas, biogas and hydrogen. They achieve <2 ppm NOx with an ultra-low NOx burner and SCR equipment, and options are available to increase boiler efficiency by 5% on average.

IWT boilers can fire renewable natural gas, biogas and hydrogen. They achieve <2 ppm NOx with an ultra-low NOx burner and SCR equipment, and options are available to increase boiler efficiency by 5% on average.

- Product Overview

- Related Resources

- Applications

- Modular designs maximize shop assembly and minimize field work.

- Convection or radiant superheaters.

- Large, water-cooled, gas-tight furnace areas.

- Boiler wall constructions are 100% water-cooled and refractory-free.

- Only single-source supplier for integrated boiler, burner, and control solutions.

- Can accommodate selective catalytic reduction (SCR) and CO catalyst.

The Modular (MED) is a 100% membrane water-cooled furnace, reducing costly, time-consuming, annual maintenance. The front and rear walls are welded and refractory-free, as well as the burner throat, when integrated with our Natcom® burner. D-style boilers can be customized to provide superheated steam. We offer both single- and dual-stage integral superheater systems with optional temperature control over turndown.

CASE STUDY

BYU Replaces Coal-Fired Boilers →

BYU replaced coal boilers with two O-type watertube boilers, a CBEX Elite firetube boiler and a HRSG, and pursued independence from local electrical grid.

Buffalo Trace Installs New Boiler System →

Buffalo Trace was able to meet changing steam demands, significant fuel savings and reduced emissions.

WHITE PAPER

- Process Steam

- Industrial Process

- Power and Utilitiesl

- Refineries and Petrochemical

- Carbon Capture

- Pharmaceutical

- Pulp and Paper

- Food & Beverage