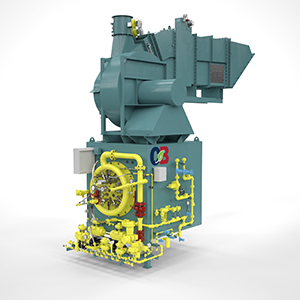

NCB Burner System

- Input Capacity (MBH): 12,000 - 360,000

- Turndown: Up to 10:1

- Emissions (ppm NOx): Uncontrolled, <30

- Mode of Operation: Single Fuel Firing

- Fuel: Gas, Oil

- Fuel Ratio Control: Single Point Positioning, Parallel Positioning, Fully Metered

- Environment: Indoor/Outdoor, Non-Hazardous

- BMS / CCS: HAWK 4500

- Elevation: Up to 5000 ft ASL

- For new boilers or retrofit applications/hr

- Natural Gas and light oil firing/hr

- Millions of configurations possible to satisfy your specific needs

- Available to < 30 ppm NOx, < 50 ppm CO

- 12 to 360 MMBTU/hr

The NCB burner is a unique packaged burner system for new boilers and retrofit markets. These burners use advanced CFD modeling, and are equipped with advanced Natcom® design features, including externally adjustable gas injectors, Class-III igniters, atomizers with coupling block valves, which you can complement with your choice among a variety of industrial-grade controls, valves, switches, and gauges.

Natcom® burners feature emissions reductions of 50% compared to flaring and can achieve emissions goals of 9 ppm NOx. The high-efficiency burner design is engineered for multi-fuel firing, including renewables.

Natcom® burners feature emissions reductions of 50% compared to flaring and can achieve emissions goals of 9 ppm NOx. The high-efficiency burner design is engineered for multi-fuel firing, including renewables.

- Product Overview

- Related Resources

- Applications

- Large capacity, from 12 to 360 MMBTU/hr

- Stand-alone burner and windbox arrangements

- Air-handling equipment package

- Rack-mounted fuel trains

- Control system with fully metered CCS available

The NCB product line features heavy-duty fan construction to reduce noise and prolong equipment life, a shipped loose or rack-mounted control panel, a custom control system in single-point, parallel, or fully metered configuration, a precise, rugged CAMLINK™ system for single-point positioning, high turndown, excess O2 control, easy access, windbox-mounted fuel trains built per ASME B31.3 and NFPA 85, and compact air-handling arrangement with integrated air flow element and silencer. In addition, the NCB product line meets all NFPA and CSA guidelines and standards.

WEBINARS

Improve Boiler Performance by Replacing the Burner →

In this webinar, attendees will learn the benefits of upgrading their boiler with a new state-of-the-art burner to improve boiler efficiency and better match facility needs.

Parallel Positioning and O2 Trim →

Parallel positioning controls help a burner to optimize its fuel-to-air ratio by using dedicated motorized actuators for the fuel and air valves.

CASE STUDY

Boiler Retrofit the Right Solution at Mount Royal University →

Reduce carbon footprint and bring boilers into compliance with local gas code

- Process Steam

- Industrial Process

- Building Heat

- Sterilization

- Humidification

- Waste Heat Recovery

- Chemical

- Power and Utilities

- Refineries and Petrochemical

- Hospital and Healthcare