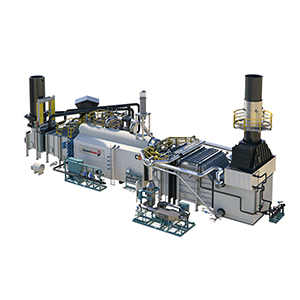

Max-Fire Series HRSG Boiler

- Gas flows up to 1,000,000 lb/hr

- Steam Generation from 10,000 to 500,000 lb/hr

- Design pressure up to 1,800 psig

- Steam temperature to 1,050 °F

- Supplemental firing with stack emissions available to less than 2 ppm NOx with SCR

The Cleaver-Brooks Max-Fire® boiler incorporates an integral furnace in a single-shop assembled, packaged HRSG design. The use of the membrane/water-cooled furnace technology allows it to be fired up to 2800°F while avoiding the use of high-maintenance refractory.

The Cleaver-Brooks HRSG achieves >80% efficiency compared to 56% for traditional technologies. It reduces up to 7.0 MMBtu/hr of fuel in conventional boilers and eliminates 2,870 tons of CO2 emissions annually per 1 MWe GT output.

The Cleaver-Brooks HRSG achieves >80% efficiency compared to 56% for traditional technologies. It reduces up to 7.0 MMBtu/hr of fuel in conventional boilers and eliminates 2,870 tons of CO2 emissions annually per 1 MWe GT output.

- Product Overview

- Related Resources

- Applications

- Completely shop-assembled boiler with integral water-cooled furnace utilizing membrane-wall construction for firing temperatures up to 2800˚F.

- Vertical (top) and horizontal gas outlet for meeting tight space requirements.

- Combination bare and finned tube sections to provide efficient heat recovery.

- Multiple finned-tube designs for optimized heat transfer.

- Large steam drums to assure ample steaming area.

- Hard or aluminum casing

- Downcomers on both ends of the boiler.

- Accommodation for selective catalytic reduction (SCR) and CO catalyst.

The Cleaver-Brooks Max-Fire boiler incorporates an integral furnace in a single shop-assembled package heat recovery steam generator (HRSG) that combines a furnace and evaporator and superheater, if applicable, with a natural circulation design. Capable of steam flows up to 500,000 lb/hr, the Max-Fire Series is offered in two different models. The MF (O-style) and MFA (A-style) models combine the waterwall combustion chamber formed from membrane wall construction with an evaporator section in a single shop-assembled boiler. The VL (O-style) and VLA (A-style) models offer an evaporator section without a furnace, but still enclosed with membrane wall construction.

WHITE PAPER

Green Steam: Firing Hydrogen in HRSG Duct Burners →

Design Considerations for Small Scale HRSGs →

CASE STUDY

BYU Replaces Coal-Fired Boilers →

BYU replaced coal boilers with two O-type watertube boilers, a CBEX Elite firetube boiler and a HRSG, and pursued independence from local electrical grid.

Ethanol Plant Increases Efficiency and Reduces Fuel Costs →

The increased efficiency in the HRSG allows this plant to reduce energy costs.

TECHNICAL WEBINAR

CHP 101 – Basics of Combined Heat and Power →

- Combined Heat and Power

- Process Steam

- District Heating

- Universities and Institutions

- Steam Heating

- Hospital and Healthcare

- Chemical

- Power and Utilities

- Refineries and Petrochemical

- Wastewater Treatment