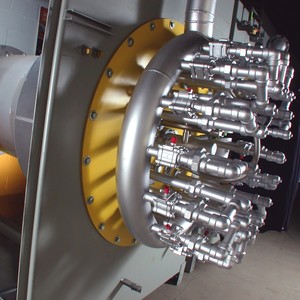

Speciality Burner Systems

- Steam, hot water, industrial drying, and thermal oxidizing applications

- 50 to 400 MMBTU/hr

- Natural gas, refinery gas, hydrogen, landfill, digester gas, tail gas, or other alternative gaseous or liquid fuels

- Available to <9 ppm NOx , <50 ppm CO

- Especially for thermal process

Cleaver-Brooks specializes in the supply of custom-engineered burner systems for the thermal processing industry. Each Natcom® burner system is designed to ensure process applications will perform to the highest possible efficiency and lowest overall emissions.

- Product Overview

- Related Resources

- Applications

- Lower NOx emissions

- Improved efficiency

- Reduced equipment footprint

- Greater flexibility to meet new challenges

The perfect burner solution for industrial drying, air heating, or thermal oxidizing processes. These custom systems feature cutting-edge engineering, system modeling, and testing to ensure the highest performance and lowest emissions in your thermal processing application.

WEBINARS

Improve Boiler Performance by Replacing the Burner →

In this webinar, attendees will learn the benefits of upgrading their boiler with a new state-of-the-art burner to improve boiler efficiency and better match facility needs.

Parallel Positioning and O2 Trim →

Parallel positioning controls help a burner to optimize its fuel-to-air ratio by using dedicated motorized actuators for the fuel and air valves.

CASE STUDY

Boiler Retrofit the Right Solution at Mount Royal University →

Reduce carbon footprint and bring boilers into compliance with local gas code

- Process Steam

- Industrial Process

- Building Heat

- Sterilization

- Humidification

- Waste Heat Recovery

- Chemical

- Power and Utilities

- Refineries and Petrochemical

- Hospital and Healthcare