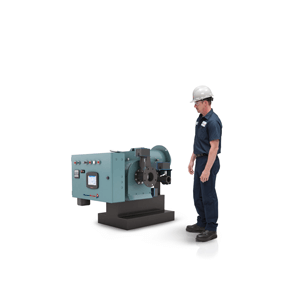

V Series

- 1.3 to 16.8 MMBTU/hr

- 31 to 400 HP

- Gas, oil, and combination

- Available to <30 ppm NOx

The ProFire® V series burners boast an aerodynamic air-damper design which permits accurate air-to-fuel settings for maximum combustion efficiency

- Burner Application Guide(Literature)

- ProFire LNVG Specifications(Technical Data)

- ProFire LNVLG Specifications(Technical Data)

- ProFire V Series Brochure(Literature)

- ProFire V Series Operation and Maintenance Manual(Technical Data)

- ProFire V Series Operation and Maintenance Manual - 2023(Technical Data)

- ProFire V Series Warranty(Technical Data)

- ProFire VG Specifications(Technical Data)

- ProFire VL Specifications(Technical Data)

- ProFire VLG Specifications(Technical Data)

- ProFire Burner Retrofit Brochure(Literature)

- Quick Product Reference Guide(Literature)

- Software to View Our 3D Models- Click Here(Drawings)

- V Series Technical Data Sheet(Technical Data)

- V Series V-105 STD Model 3D(Drawings)

- V Series V-126 to 168 STD Model 3D(Drawings)

- V Series V-25 to 34 STD Model 3D(Drawings)

- V Series V-42 to 54 STD Model 3D(Drawings)

- V Series V-63 to 84 STD Model 3D(Drawings)

- Product Overview

- Related Resources

- Applications

- Unique air-damper design features a dual-blade configuration offering precise control of combustion air flow throughout the entire firing range

- Cam trim option with 14-point adjustment range for consistent air/fuel ratios

- UL/cUL listed

Suitable for firetube, watertube, firebox and cast iron boilers, the standard V series offers natural gas, propane gas, pressure atomized #2 oil and combination gas/oil fuel options from 1.3 to 16.8 MMBTU. The low NOx V series offers natural gas, propane gas, pressure atomized #2 oil, and combination gas/oil fuel options from 1.3 to 14.7 MMBTU. Using advanced technology, the V series offers high turndown on natural gas and low emission capability. The forced-draft design provides clean and efficient combustion. Design features also include a top- or rear-mount panel option, Induced FGR (Flue Gas Recirculation), an FGR modulating valve, and No. 2 oil capability for backup fuel.

WEBINARS

Improve Boiler Performance by Replacing the Burner →

In this webinar, attendees will learn the benefits of upgrading their boiler with a new state-of-the-art burner to improve boiler efficiency and better match facility needs.

Parallel Positioning and O2 Trim →

Parallel positioning controls help a burner to optimize its fuel-to-air ratio by using dedicated motorized actuators for the fuel and air valves.

CASE STUDY

Boiler Retrofit the Right Solution at Mount Royal University →

Reduce carbon footprint and bring boilers into compliance with local gas code

- Process Steam

- Industrial Process

- Building Heat

- Hospital and Healthcare

- Laundry and Dry Cleaning